Custom Size Industrial Storage Racks Supplier: What to Ask Before Placing a Bulk Order

Why Choose Custom Size Racks for Your Warehouse? In today’s era of lean logistics and precision warehousing, custom size industrial storage racks…

Why Choose Custom Size Racks for Your Warehouse?

In today’s era of lean logistics and precision warehousing, custom size industrial storage racks have become the backbone of operational efficiency and space optimization. Whether you run a large distribution center, a busy production line, or a heavy-duty equipment warehouse, a racking system tailored to your site and inventory can dramatically boost safety and productivity.

Standard racks may offer quick delivery and clear pricing, but they often fall short when it comes to fitting unique site constraints—such as building columns, fire lanes, roof trusses—or matching special pallet sizes, load weights, and forklift models. Custom solutions, by contrast, adapt seamlessly to your facility’s layout and workflow, ensuring zero wasted space. For bulk orders, customizing means a unified, scalable solution—ideal for businesses planning future expansion.

6 Critical Questions to Ask Before Placing a Bulk Order

1. Materials, Craftsmanship, and Corrosion Resistance

Heavy-duty racks operate under constant load, so material strength and surface treatment determine lifespan and safety. Ask your supplier:

- What grade and thickness of steel are used (e.g., Q235, SS400)?

- What surface treatment is applied (e.g., acid pickling, phosphating, electrostatic powder coating, hot-dip galvanizing)?

- What is the coating thickness and adhesion standard? Can they provide test reports?

High-quality finishes prevent rust and corrosion, ensuring stability even in humid or variable-temperature environments.

2. Load Capacity and Structural Stability

Load capacity is the core performance metric—distinguish between static and dynamic loads.

- What is the rated load per level and per bay (including dynamic and impact factors)?

- How are uprights, beams, and bracing designed and connected (e.g., boltless, bolted)?

- Can they provide structural calculation sheets or compliance with local standards (OSHA, DIN, GB)?

A robust design prevents deformation from long-term use or accidental forklift impacts.

3. Design Capability and Professional Fit-Out

Top suppliers should offer warehouse planning expertise.

- Do they provide free site surveys or detailed layout plans based on drawings?

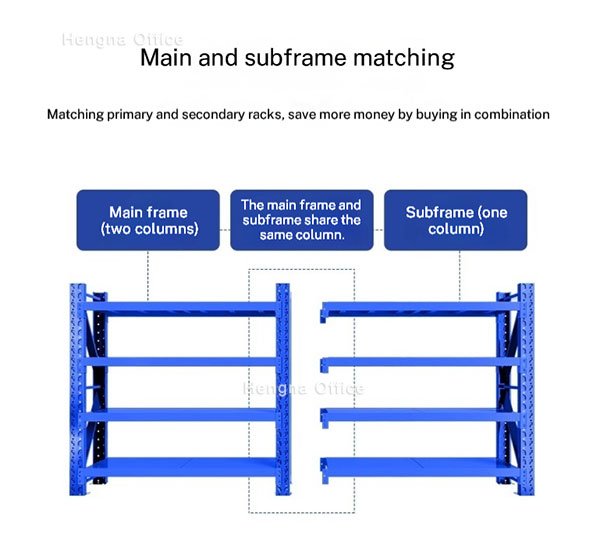

- Do they optimize main and add-on bays to save material and cost?

- Does the design account for aisle width, forklift turning radius, fire safety, and lighting?

A well-thought-out plan maximizes storage density and operational flow.

4. Installation Service and Delivery Timeline

Custom racks require professional installation.

- Does the price include installation by trained crews?

- What is the total lead time from order to completion? Can bulk orders be delivered in phases?

- How will they coordinate with other contractors on-site?

Clear timelines and installation plans prevent costly delays.

5. After-Sales Support and Warranty

Long-term reliability depends on service quality.

- What is the warranty period and scope (structure, coating, etc.)?

- Do they offer periodic safety inspections or maintenance guidance?

- Can they provide compatible extensions or modifications later?

A strong warranty and support protect your investment for years.

6. Price Structure and Payment Terms

Understand exactly what you’re paying for.

- Is the quote all-inclusive (design, materials, production, shipping, installation, taxes)?

- Are there volume discounts for bulk orders?

- What are the payment milestones (deposit, progress payments, final balance)?

- How are price adjustments handled for design changes or material cost fluctuations?

Transparent pricing avoids budget surprises.

Treat Your Supplier as a Long-Term Partner

Choosing a custom size industrial storage racks supplier isn’t just a purchase—it’s a partnership. Successful bulk orders start with thorough, professional communication. By asking these seven questions, you’ll minimize risks and secure a safe, efficient, and economical storage system that grows with your business. In a competitive market, a professional racking system is the silent backbone of your supply chain—strong, reliable, and always ready to support your success.