Starter vs. Add-on Shelving Units: How to Reduce Warehouse Setup Costs by 30%

In the competitive world of logistics and warehousing, every square foot of space and every dollar of the budget counts. Whether you…

In the competitive world of logistics and warehousing, every square foot of space and every dollar of the budget counts. Whether you are setting up a new distribution center, upgrading an e-commerce fulfillment warehouse, or organizing a retail backroom, the cost of racking systems is a significant investment.

One of the most common mistakes we see business owners make is purchasing standard, standalone shelving units for their entire facility. While this works, it is financially inefficient.

Today, we are going to reveal a simple industry secret that can reduce your initial racking investment by up to 30%: mastering the combination of Starter Units (Main Frames) and Add-on Units (Sub Frames).

What is the Difference? Starter vs. Add-on Shelving Units Explained

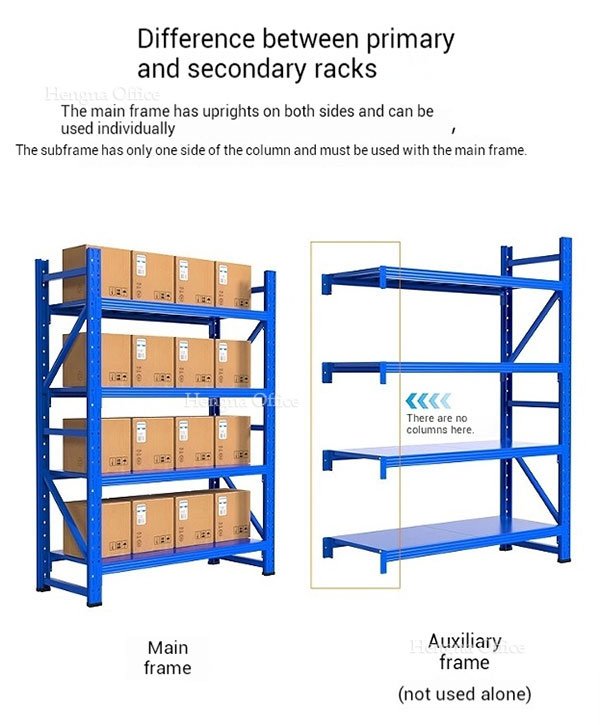

Before we dive into the math of saving money, it is crucial to understand the structural difference between these two components. In the industry, we often refer to this as the “Main and Sub-frame” system.

1. The Starter Unit (The Main Frame)

A Starter Unit is a completely standalone shelving bay. It is the anchor of your shelving row.

- Components: It consists of two upright frames (the vertical posts) and the corresponding beams or shelves.

- Function: It can stand alone anywhere in the warehouse without needing support from another unit.

- When to use it: You always need at least one Starter Unit to begin a row of shelving.

2. The Add-on Unit (The Sub Frame)

An Add-on Unit is designed to attach to an existing Starter Unit. It cannot stand alone.

- Components: It consists of only one upright frame and the corresponding beams or shelves.

- Function: It connects to the upright post of the previous unit, sharing that common leg.

- When to use it: You use these to extend the length of your shelving row indefinitely.

Visual Tip: Imagine a row of shelving like a chain. The Starter Unit is the first link, and every subsequent link is an Add-on Unit.

The Math: How “Main & Add-on” Logic Saves You 30%

Why does this distinction matter for your wallet? The answer lies in the steel consumption.

When you buy individual standalone racks (Starter Units) and place them side-by-side, you are effectively doubling the uprights where the shelves meet. You are paying for two metal legs when you only need one.

By utilizing Add-on Units, you eliminate the redundant upright frame.

Let’s Look at the Numbers

| Configuration Strategy | Components Required | Cost Implication |

| Option A: 5 Standalone Units | 10 Upright Frames + Shelves | High Cost (Paying for 10 legs) |

| Option B: 1 Starter + 4 Add-ons | 6 Upright Frames + Shelves | Low Cost (Paying for only 6 legs) |

The Result: In Option B, you save the cost of 4 heavy-duty upright frames. For large warehouses with hundreds of rows, this reduction in material cost—combined with lower shipping weights—can easily translate to 30% total savings on your project.

Beyond Cost: 3 Reasons to Choose Custom “Add-on” Systems

Saving money is the primary driver, but customized Starter and Add-on configurations offer other operational benefits.

1. Maximized Space Utilization (No Gaps)

When you place standalone shelves next to each other, there is often a small, useless gap between the uprights. Over a long row, this wastes valuable floor space. An Add-on system creates a continuous, seamless run of shelving, maximizing your storage density.

2. Enhanced Stability and Safety

In a Starter + Add-on configuration, the entire row acts as a single, unified structure. This interconnectedness often provides better lateral stability compared to individual units standing side-by-side, especially when storing heavy industrial loads.

3. Customized for Your Industry Needs

Standard off-the-shelf units are “one size fits all.” However, industries like electronics, food, and pharmaceuticals often have specific needs. Custom manufacturing allows you to:

- Color Coding: As seen in our product lines, we offer racks in Blue, White, and Black. You might use White for clean-room/medical environments to spot dust easily, or Blue for standard heavy equipment.

- Dimensions: If your warehouse has low ceilings or obstructive columns, a custom Main/Sub frame solution can be built to the exact inch, ensuring no vertical space is wasted.

When Do You Need Customization? (The Checklist)

If you are unsure whether you need a standard solution or a custom Starter/Add-on configuration, check if any of the following apply to you:

- Irregular Items: Your products are oddly shaped (long, bulky, or non-stackable) and don’t fit on standard 4-foot shelves.

- Specific Warehouse Constraints: You have pillars, varying ceiling heights, or specific aisle width requirements that standard racks violate.

- Industry Compliance: You are in the food or medical sector requiring specific powder coatings for hygiene and cleaning (e.g., smooth surfaces that don’t trap bacteria).

- Brand Aesthetics: You want your warehouse or showroom to reflect your corporate identity (e.g., using brand colors).

Smart Planning Pays Off

Your warehouse racking is the skeleton of your business operation. By choosing a smart combination of Starter and Add-on units, you aren’t just buying steel—you are buying efficiency. You reduce material waste, lower shipping fees, and create a more stable, professional-looking storage facility.

Don’t pay for legs you don’t need.

At Hengna Office Furniture, we specialize in non-standard, custom warehouse solutions. Whether you need a heavy-duty blue industrial rack or a clean white display shelf for medical supplies, we can design the perfect Main and Sub-frame layout for your floor plan.