How to Choose Heavy Duty Industrial Pallet Racking Systems for 300kg+ Load per Level

In the landscape of modern warehousing and logistics, heavy-duty industrial pallet racking systems are more than just furniture—they are the skeletal framework…

In the landscape of modern warehousing and logistics, heavy-duty industrial pallet racking systems are more than just furniture—they are the skeletal framework of your operational efficiency and safety. When your inventory involves large raw materials, finished product pallets, or heavy machinery components exceeding 300kg per level, the stakes of your storage choice escalate significantly.

Selecting the right system isn’t just about organizing space; it is about mitigating risk, ensuring workplace safety, and optimizing long-term operational costs. This guide breaks down the critical considerations and procurement steps for high-capacity industrial storage.

The Criticality of the 300kg+ Load Capacity

Racking systems that support over 300kg per level fall squarely into the “Heavy Duty” category. Unlike light or medium shelving, these systems require superior material strength, advanced structural engineering, and rigorous safety standards.

An improper choice can lead to devastating consequences, including beam deflection, structural collapse, inventory loss, and—most importantly—personnel injury. Therefore, selecting a system capable of stable load bearing is a scientific process that requires professional planning.

6 Core Selection Criteria for Industrial Racking(Heavy Duty Industrial Pallet Racking )

1. Load Capacity and Structural Engineering: Beyond the Label

When a supplier promises “300kg+ capacity,” you must look deeper into the engineering:

- Dynamic vs. Static Loading: Ensure the rating refers to dynamic loading—the ability to remain safe during the repetitive stresses of forklift interaction—not just a static weight limit.

- Upright and Beam Thickness: Quality racks utilize thickened cold-rolled steel. Beams should feature internal reinforcement ribs or multi-layer composite designs to prevent sagging over years of constant pressure.

- Triangular Stability Principles: The overall stability depends on support structures like diagonal bracing or back-ties that utilize triangular geometry to resist horizontal forces, preventing the rack from swaying or tipping.

2. Material and Manufacturing: The Foundation of Durability

The longevity of your warehouse infrastructure starts with the raw materials:

- High-Grade Steel: Look for high-strength steel grades (such as Q235B) with documented yield strength.

- Advanced Surface Treatment: Heavy-duty racks often face harsh industrial environments. Features such as anti-corrosion and anti-rust finishes are vital. High-thickness electrostatic powder coating is a reliable standard that extends the rack’s life in humid or temperature-fluctuating warehouses.

- Precision Connection Details: Inspect the locking pins and bolts connecting the beams to the uprights. They must be robust, easy to install, and designed with anti-dislodgement features to prevent accidental detachment during forklift operation.

3. Decking and Safety Accessories: The Interface of Support

For loads exceeding 300kg, standard timber or thin sheet metal is no longer adequate:

- Heavy-Duty Decking: Opt for thickened steel decking, such as wire mesh or solid steel plates, ensuring the edges are flanged or reinforced to prevent warping.

- Safety Hardware: Every level must be equipped with safety pins or beam locks. Furthermore, investing in upright protectors and货物挡杆 (load stoppers) is essential to safeguard against the accidental impacts common in high-frequency forklift environments.

4. Flexibility and Scalability for Business Growth

A rigid system is a fast-obsoleting system. Your racking should offer:

- Adjustability: Uprights should feature a versatile hole pitch, allowing you to adjust shelf heights as your inventory dimensions change over time.

- Modular “Starter and Add-on” Kits: By using a combination of “Starter” units (two uprights) and “Add-on” units (sharing one common upright), you can save significant space and cost while building continuous rows. This “buy in combination” strategy is both beautiful and practical.

5. Supplier Expertise and Service Standards

When sourcing industrial equipment, you are buying a partnership:

- Design and Planning: A professional supplier provides warehouse layout designs and precise load calculations rather than just shipping hardware.

- Quality Assurance: Confirm if the supplier offers installation services and conducts post-installation testing for verticality, leveling, and load-bearing performance.

- Proven Track Record: Check industry certifications and past case studies, particularly those involving high-density storage or heavy mold management.

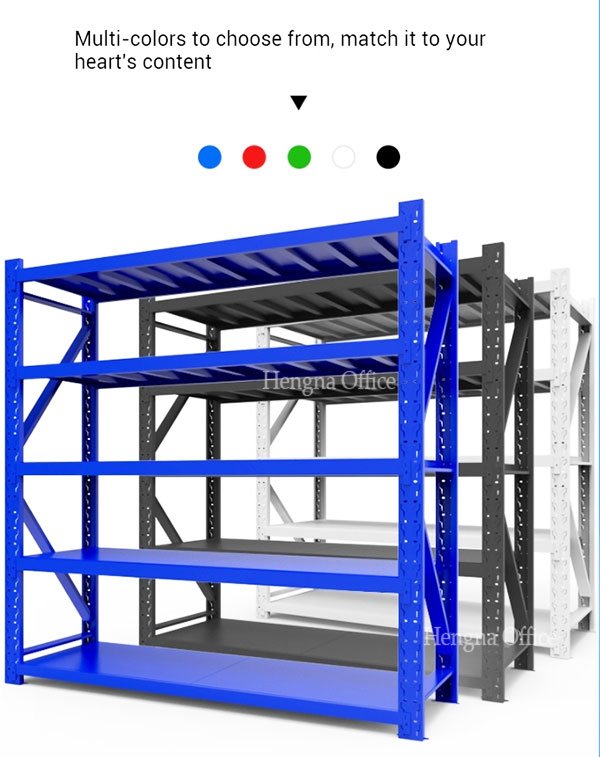

6. The Intersection of Aesthetics and Utility

Professionalism in the warehouse leads to better operations. Many modern heavy-duty racks come with customizable powder coatings. Choosing colors that align with your corporate identity or safety zones (such as industrial blue, orange, or grey) creates a workspace that is as organized as it is clean.

The Strategic Procurement Process

- Needs Assessment: Define your maximum pallet dimensions, weight, turnover frequency, and the specific forklift models in use.

- Precise Site Measurement: Measure clear height, column spacing, and the location of fire exits and utility lines.

- Scheme Acquisition: Invite 2-3 professional suppliers to provide preliminary layouts and load-bearing schemes based on your measurements.

- Technical Inquisitiveness: Challenge the suppliers on the six core standards mentioned above, specifically regarding material thickness and anti-corrosion treatments.

- Balanced Decision Making: Balance the initial price against the technical scheme, service quality, and the supplier’s reputation. The cheapest quote often hides the highest long-term risk.

Choosing a heavy-duty industrial pallet racking system for 300kg+ loads is a high-level technical decision. It is an investment in the foundational infrastructure of your company’s logistics. By focusing on structural stability, material science, and professional service, you create a storage environment that is not only safe and efficient but also scalable as your business grows.

Remember, the strongest racking system is the one that remains silent and rock-solid under a daily heavy load, serving as the invisible backbone of your industrial success.