Main vs. Sub-Frame Shelving: How to Save Up to 30% on Warehouse Storage Costs

In the world of B2B warehousing and industrial logistics, floor space is money, but the infrastructure you put on that floor determines…

In the world of B2B warehousing and industrial logistics, floor space is money, but the infrastructure you put on that floor determines your long-term ROI. As warehouse managers and procurement officers face rising operational costs in 2026, the demand for smarter, more cost-effective storage has never been higher.

Understanding the differences between Main vs. Sub-Frame Shelving is crucial for maximizing efficiency.

Choosing between Main vs. Sub-Frame Shelving can lead to significant cost savings and improved workflow.

One of the most effective yet often misunderstood strategies to reduce capital expenditure is the use of Main vs. Sub-Frame Shelving (Add-on) shelving structures. By understanding this structural configuration, businesses can save up to 30% on equipment costs without compromising on load capacity or safety.

When analyzing Main vs. Sub-Frame Shelving, consider the overall space utilization.

What is Main and Sub-Frame Shelving?

The Main vs. Sub-Frame Shelving setup not only saves costs but also enhances flexibility in the warehouse.

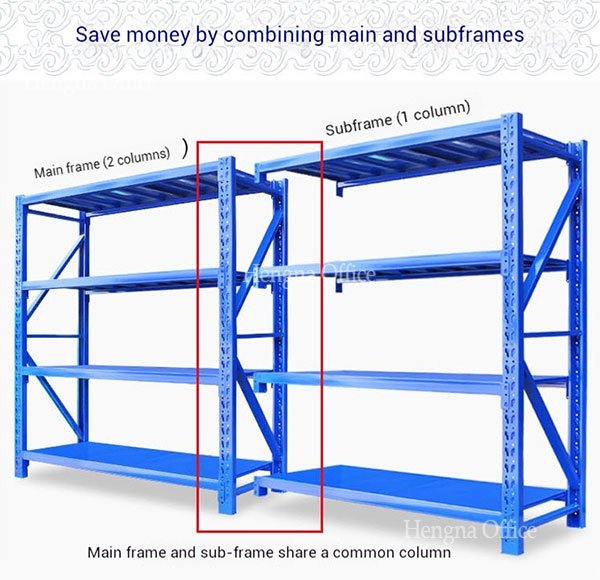

To understand the savings, we first need to define the components. Traditional shelving units are often thought of as independent boxes. However, in an industrial setting, shelving is rarely stand-alone; it is installed in long, continuous rows.

The Main Frame (Starter Unit)

A Main Frame is a complete, stand-alone shelving unit. it consists of:

Understanding Main vs. Sub-Frame Shelving helps optimize your storage solutions effectively.

- Two Upright Frames (Columns): The vertical supports on both the left and right sides.

- Beams and Layers: The horizontal supports and the shelves themselves.

The Sub-Frame (Add-on Unit)

With Main vs. Sub-Frame Shelving, businesses have the opportunity to rethink their storage strategies.

Calculating costs with Main vs. Sub-Frame Shelving configurations leads to better financial decisions.

Assessing Main vs. Sub-Frame Shelving can provide insights into effective warehouse management.

A Sub-frame (also known as an Add-on unit) is a shelving unit that only has one upright frame. It is designed to “hitch” onto an existing Main Frame or another Sub-frame. Because it shares a vertical column with the unit next to it, it cannot stand alone.

The comparison of Main vs. Sub-Frame Shelving highlights the advantages of shared structures.

The Math of Savings: Why It Costs 30% Less

The primary cost of heavy-duty steel shelving is driven by the weight and grade of the steel used in the upright columns. In a standard warehouse layout consisting of a row of 10 shelving units, the structural requirements change significantly depending on your configuration.

Comparison:Main vs. Sub-Frame Shelving Configuration:

| Feature | 10 Independent Units | 1 Main + 9 Sub-frames |

| Total Uprights Required | 20 Uprights | 11 Uprights |

| Material Usage | High (Redundant steel) | Optimized (Shared columns) |

| Total Cost Index | 100% | ~70% – 75% |

| Installation Speed | Moderate | Fast (Interlocking design) |

| Stability | Individual | Integrated (Row-based) |

By eliminating 9 redundant uprights in a 10-unit row, you are essentially removing nearly half of the vertical steel weight. This translates directly into:

- Lower Purchase Price: Direct savings from the manufacturer.

- Reduced Shipping Costs: Less weight and smaller volume in the shipping container (CKD packaging).

- Lower Labor Costs: Fewer columns to align and bolt to the floor.

Structural Integrity: Is It Just as Strong?

A common concern for B2B buyers is whether a shared upright reduces the load-bearing capacity of the rack. The answer is no, provided the rack is engineered for shared loads.

In a heavy-duty steel racking system, the upright is designed to handle the vertical compression from both the left and right beams simultaneously. In fact, a continuous row of main and sub-frames often provides greater lateral stability than a series of disconnected, independent units.

Key Safety Features to Look For:

- Steel Grade: Ensure the uprights are made of high-quality cold-rolled steel (e.g., Q235B).

- Safety Pins: Every beam-to-upright connection must have a safety locking pin to prevent accidental dislodgment by forklifts.

- Footplates: Heavy-duty base plates should be bolted to the warehouse floor to ensure the row remains vertical under maximum load.

Many organizations are turning to Main vs. Sub-Frame Shelving for cost-effective solutions.

Implementing Main vs. Sub-Frame Shelving is vital for modern logistics centers.

Top 3 Applications for Main and Sub-Frame Shelving

1. Large-Scale Logistics Centers

Utilizing Main vs. Sub-Frame Shelving enhances organization in manufacturing environments.

Retailers benefit from Main vs. Sub-Frame Shelving for their back-of-house storage needs.

In facilities with thousands of SKUs, rows can stretch for 50 meters or more. Implementing a Main-Sub strategy here isn’t just a suggestion; it is a financial necessity to remain competitive.

The advantages of Main vs. Sub-Frame Shelving are clear in maximizing storage efficiency.

2. Industrial Manufacturing Workshops

Factories storing heavy molds or raw materials need the “Heavy Duty” aspect of steel shelving. Using sub-frames allows for a clean, organized look that keeps the workshop floor clear while maximizing vertical space.

3. Retail Back-of-House Storage

Large retailers with high inventory turnover use these systems to organize bulk stock. The modularity allows them to add more sub-frames as their inventory grows during peak seasons.

How to Plan Your Warehouse Layout for Maximum ROI

To achieve that 30% saving, procurement officers should follow a specific planning workflow:

- Measure Your Run Length: Determine the total length of the wall or aisle where the shelving will sit.

- Determine Unit Width: If your aisle is 10 meters long and you use 2-meter wide units, you need 5 units total.

- The “1+N” Rule: For every continuous row, buy 1 Main Frame and N-1 Sub-frames.

- Factor in “Obstacles”: If a row is interrupted by a fire door or a pillar, the row must end, and a new Main Frame must start on the other side.

When comparing options, Main vs. Sub-Frame Shelving stands out for its strength and reliability.

Why Heavy-Duty Steel is the Gold Standard

While plastic or light-duty wood might work for home garages, B2B environments demand heavy-duty steel.

- Impact Resistance: Warehouse environments are rough. Steel can withstand the occasional bump from a pallet jack.

- Adjustability: As your product dimensions change, the “butterfly hole” or “teardrop” design of the uprights allows you to move beams up or down in 50mm or 75mm increments.

- Longevity: Powder-coated steel resists rust and corrosion, especially in non-climate-controlled environments.

Turning Infrastructure into Competitive Advantage

Smart procurement is about more than just finding the lowest price; it is about finding the most efficient configuration. By utilizing the Main and Sub-frame structure for your heavy-duty steel shelving, you directly reduce your overhead while maintaining a professional, safe, and scalable storage environment.

Investing in Main vs. Sub-Frame Shelving can significantly improve your warehouse operations.

Ultimately, the choice of Main vs. Sub-Frame Shelving affects your overall efficiency and savings.

For businesses looking to optimize their 2026 budget, the math is clear: Shared uprights equal shared savings.