Custom Warehouse Racking Solutions: Optimizing Layouts for Limited Space and Irregular SKUs

In the fast-paced world of logistics and supply chain management, the “one-size-fits-all” approach is rapidly becoming a myth. Every warehouse manager knows…

In the fast-paced world of logistics and supply chain management, the “one-size-fits-all” approach is rapidly becoming a myth. Every warehouse manager knows the frustration: you buy standard pallet racking, only to realize it doesn’t fit around that structural column, or your new product line is too long, too bulky, or too heavy for standard shelf depths.

The result? Dead space. And in warehousing, dead space equals lost revenue.

Whether you are managing a distribution center for automotive parts or a climate-controlled storage facility for pharmaceuticals, the efficiency of your layout dictates your profitability. This is where Custom Warehouse Racking Solutions come into play.

Today, we will explore why standard off-the-shelf racking is failing modern businesses and how customizing your storage system can optimize your layout for limited spaces and irregular SKUs.

The “Square Peg, Round Hole” Problem

Most standard industrial shelving comes in fixed dimensions—usually designed for standard 40×48 inch pallets. But what happens when your inventory isn’t standard? What if your building isn’t a perfect rectangle?

Forcing standard racks into a unique space leads to:

- Reduced Storage Density: Wasting vertical space because beam levels aren’t adjustable enough.

- Operational Inefficiency: Forklifts taking longer to maneuver around poorly placed aisles.

- Safety Hazards: Overhanging products on shelves that are too shallow.

To stay competitive, successful warehouses are switching to bespoke, engineered storage solutions.

4 Critical Reasons to Choose Custom Racking

Based on industry data and client feedback, there are four primary drivers for choosing custom fabrication over stock shelving.

1. Handling Items with Special Properties (Irregular SKUs)

Not all inventory comes in neat cardboard boxes. Many industries deal with “ugly freight”—items that are difficult to stack or store.

- Shape & Size: Long PVC pipes, car bumpers, tires, or rolls of fabric cannot sit safely on standard decking. Custom racking allows for deeper bays, cantilever arms, or specific dividers.

- Weight Load: Heavy machinery parts may exceed the weight capacity of standard commercial shelving. Custom solutions allow for reinforced steel gauges (uprights and beams) to handle extreme loads safely.

Pro Tip: If your SKUs overhang your shelf by more than 2 inches, you are creating a safety hazard. Custom depth is the only safe solution.

2. Overcoming Warehouse Space Constraints

Real-world warehouses are rarely perfect empty boxes. They have character—and obstacles.

- Structural Obstacles: Support columns, low-hanging ventilation ducts, or fire suppression systems often block standard rack rows. Custom designing allows you to build around these obstacles, turning dead corners into usable storage.

- Vertical Utilization: If you have a high ceiling but your standard rack only goes up 10 feet, you are wasting 50% of your volume. Custom uprights can be manufactured to match your exact ceiling height, maximizing vertical density.

3. Meeting Specific Industry Standards

Different sectors operate under different rules. A rack that works for an auto shop might be illegal in a food processing plant.

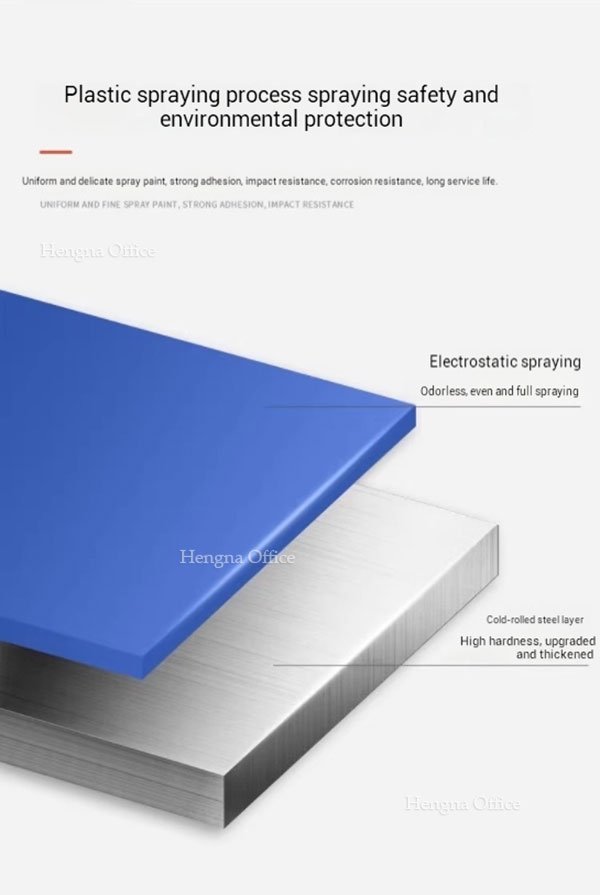

- Medical & Food: These industries require hygiene-compliant surfaces. Custom powder-coated finishes (like the white racks shown in our product line) make it easier to spot dirt and resist corrosion from frequent cleaning.

- Electronics (ESD): Semiconductor storage may require anti-static shelving materials to protect sensitive components.

4. Brand Consistency and Aesthetics

In the modern era, the warehouse is often part of the showroom or client tour.

- Brand Identity: Companies are increasingly requesting racks in their brand colors (e.g., specific shades of Blue, Red, or Black) to create a professional, cohesive look.

- Customer Experience: For businesses like “Cash & Carry” wholesalers, the rack is the retail display. A clean, custom-colored racking system enhances the customer’s perception of product quality.

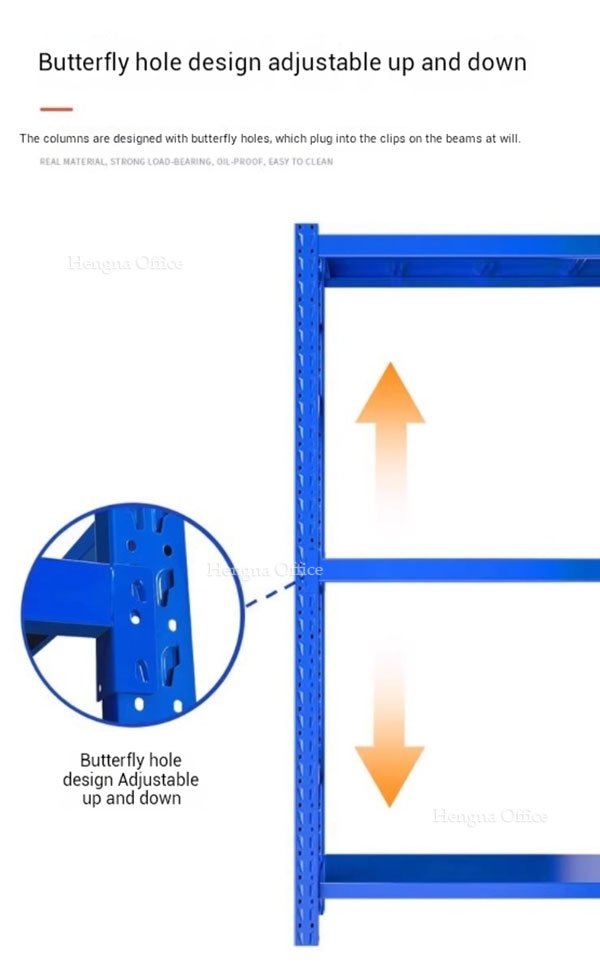

Feature Spotlight: The “Butterfly Hole” Advantage

When we talk about “Custom Solutions,” we don’t mean “Permanent & Unchangeable.” In fact, the best custom racking is highly adaptable.

One of the key features of our high-end custom racking is the Butterfly Hole Design.

Why Does Hole Design Matter?

The connection point between the upright column and the horizontal beam dictates the rack’s flexibility.

- Tool-Free Adjustment: The butterfly hole shape allows beams to slot in securely without bolts, using gravity and safety pins to lock in place.

- Micro-Adjustability: As your inventory changes (e.g., switching from large boxes to small bins), you can adjust the beam levels up or down in small increments.

The Benefit: You don’t need to buy new racks when your product line changes. You simply reconfigure your custom layout to fit the new SKUs.

Comparison: Standard vs. Custom Racking

Is custom racking worth the investment? Let’s look at the breakdown.

| Feature | Standard “Big Box” Racking | Custom Engineered Solutions |

| Space Utilization | Low: Often leaves gaps near columns or ceilings. | High: Uses every available inch of floor and vertical space. |

| Load Capacity | Fixed: Standard limits (e.g., 2000 lbs/level). | Variable: Engineered to hold your specific weight requirements. |

| SKU Compatibility | Limited to standard pallets/boxes. | Perfect for pipes, tires, drums, and odd shapes. |

| Aesthetics | Usually standard grey or orange. | Available in Blue, White, Black, or Brand Colors. |

| Long-Term ROI | Lower upfront cost, higher risk of damage/inefficiency. | Higher upfront cost, Maximum Efficiency & Durability. |

How to Plan Your Custom Layout

If you are ready to move away from inefficient storage, here is a simple checklist to get started with a custom order:

- Audit Your Inventory: List your largest, heaviest, and most awkwardly shaped items. Measure them.

- Map Your Floor: Mark down the location of pillars, doors, and ceiling obstructions.

- Choose Your Color: Do you need White for hygiene, Blue for industrial standard, or Black for a sleek look?

- Define the Load: Be realistic about the maximum weight per shelf level.

Your warehouse racking is the skeleton of your business. If the skeleton is weak or ill-fitting, the body cannot function efficiently.

By choosing Custom Warehouse Racking Solutions, you aren’t just buying steel shelves; you are investing in a system that adapts to your unique space limitations and handles your specific SKUs with ease. whether you need the adjustability of the butterfly hole design or the hygiene compliance of specialized coatings, custom is the path to profitability.

Ready to optimize your space? Don’t let pillars and low ceilings limit your growth. Contact our engineering team today to design a racking solution that fits your business perfectly.